Cabinets are wonderful devices. The corner curio solves the problem of eliminating wasted corner space in a dining room and elegantly displaying your finest items.

In this situation, the previous homeowner wanted theirs to resemble built-ins, so they trimmed out the edges.

However, they had a problem with the dining room light switch—which was installed with no forethought of cabinets or integrating them onto the wall. They oddly chose to contour the molding on top of half the light switch cover. The result was using the switch was awkward and cleaning the cabinet was less than ideal. The switch was also put into a defacto unserviceable state for an electrician.

Since we were about to upgrade and modify this circuit, servicing the switch was required.

Instead of a basic single-pole single-throw switch, we were making the lighting circuit into a three-way switch set-up. One in the kitchen and this one depicted here at the living room threshold.

Its placement was just wrong for the new plans.

When it came to the new homeowner, it was a simple ask; “move the light switch over about four inches“. The reason they didn’t know they can’t get there from here was, most people don’t know what’s inside the walls, or why it’s there.

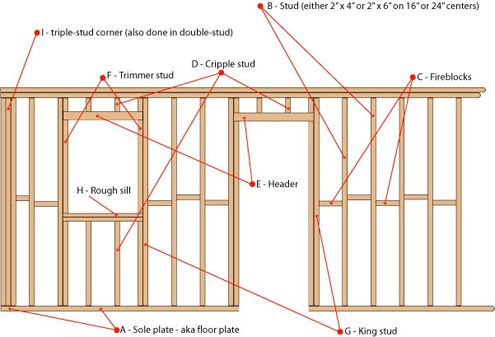

Where ever there’s an opening in a wall that you walk through, there’s at least one extra two-by-four hiding in there to keep the beam above the opening up in place. Compounding the issue was this is a load-bearing wall. Furthermore, on the other side of the wall from the switch is a partition wall dividing the bedrooms from the living room and dining room; we always add extra 2×4 lumber in places connecting walls.

Not all was lost here because one of the old work options in gang boxes is the shallow-work type. If the chosen light switch and the wiring complexity of the existing gang-box are amenable, this shallow box can be a viable solution. It has a depth of only 1.25″ so depending on the wall coverings, chiseling away the lumber might not be needed at all.

As it turned out, we did need to chisel a bit, but because it was the King-Stud instead of the Jack-Stud, it’s not the primary load-bearing stud for the header that runs across the opening, so it’s going to pass building code scrutiny.

We were able to nick off only a quarter inch of the King-Stud to get it to fit because the lathe & plaster makeup of the wall was fairly thick.

The fortuitous nature of the interior wallboard (not reinforced by a metal lathe), allowed us to use the removed piece as the patch over the old location of the switch.

The final trim that the original installer of the curio cabinets used was not available to buy anywhere we looked after 5 different lumber/hardware/big-box stores and on the websites of some of them.

It was a non-wood type material they originally used so the shape was very unique and its delicate edges wouldn’t be feasible for a store to stock and sell.

We were able to recreate the finished trim work from standard wooden cove molding and the clever use of a table saw.

Now this job is all done except for the painting, which they want to do for themselves.